Har du et elektronisk montageprojekt, vi kan hjælpe med?

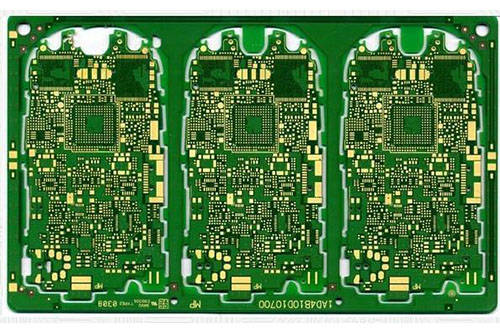

PCB-fabrikation

DYC Electronic has a full technical knowledge and PCB manufacturing experience in PCB fabrication (also called printed circuit board manufacturing or printed circuit board fabrication). From single layer board to 32 layer board, from flex PCB to rigid-flex PCB, DYC can offer the complete PCB solution.

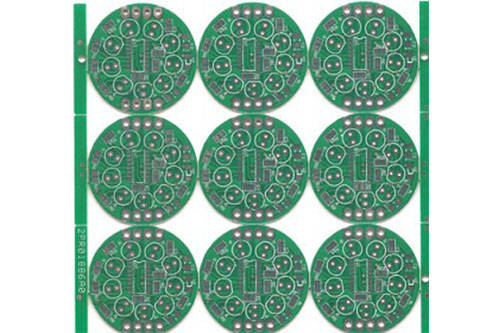

PCB Prototype

1-32 Layer PCB Prototype for Rigid, Flex and Rigid-Flex board, we offer 24 hours Quick Turn PCB prototype.

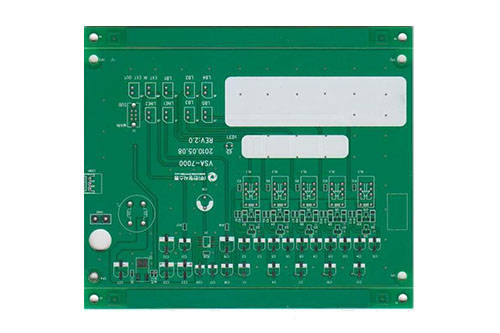

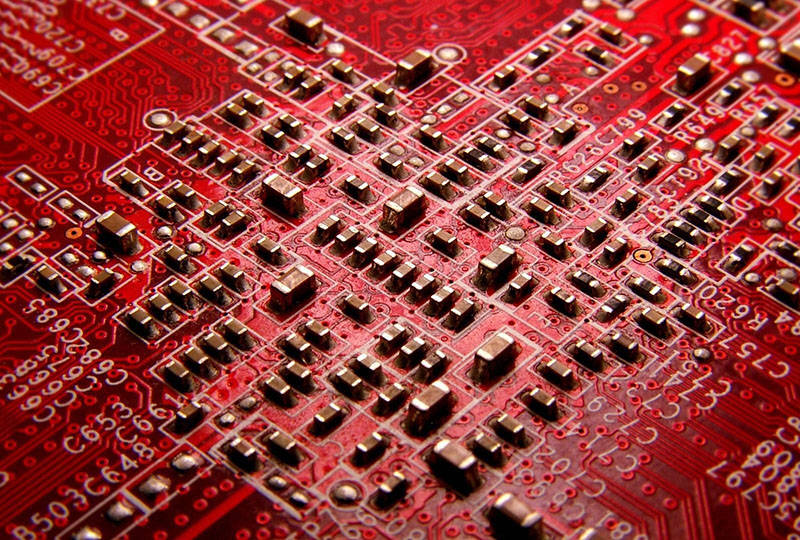

Rigid PCB

From single layer to 32 layers rigid printed circuit board with no minimum order requirement.

Impendence Control PCB

We offer free impedance control calculations suggestions for your controlled impedance PCB.

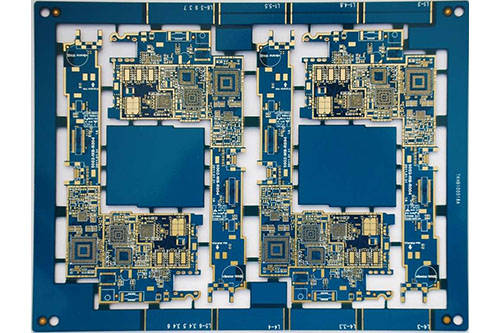

HDI PCB

HDI PCBs offers higher circuitry density per unit so that can make your device more portable.

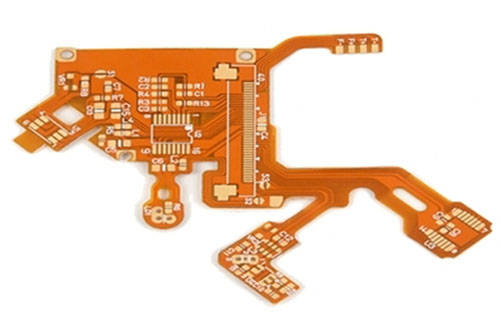

Flexible PCB

We produce 1-4 layers flexible Printed circuit board from fabrication and assembly.

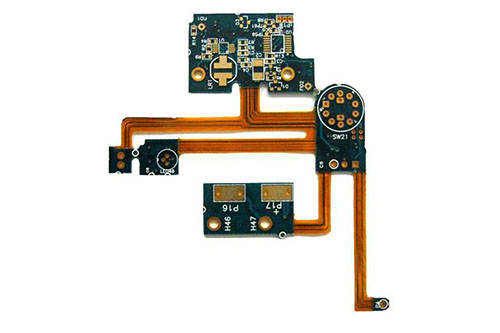

Rigid Flex PCB

A circuit board made by combining hard and soft boards to reduce connectors and increase the reliability of interconnections

Aluminum PCB

Our 1-6 layers aluminum PCB fabrication will give you best performance and low-cost solution.

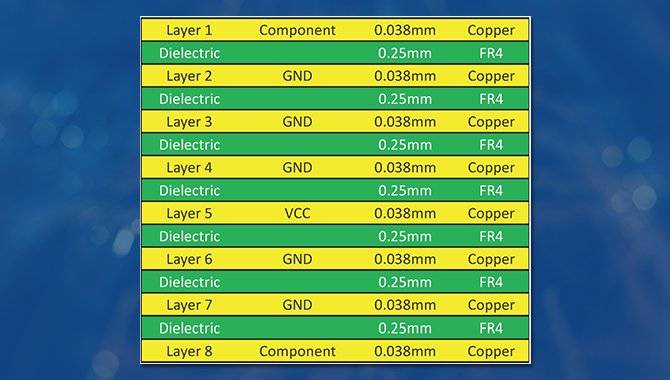

DYC: Your Leading Layer Stack-up Supplier in China

DYC Layer Stackup is the basic process to avoid emission, crosstalk, and all other kinds of disturbances of high-speed applications.

There is really no limit to the number of layers that can be fabricated in a multilayer PCB, and DYC’s maximum capability is 32 layers.

Most of the boards we are building every day are less than 16 layers. To find out more about multilayer boards layer stack-up information, please feel free to contact our sales.

We also offer free stack-up checking, you are more than welcome to contact us.

- Over 10 years’ experience

- Highly trained and skilled engineers

- Cost-effective PCB layer stackup

- Fast turnaround

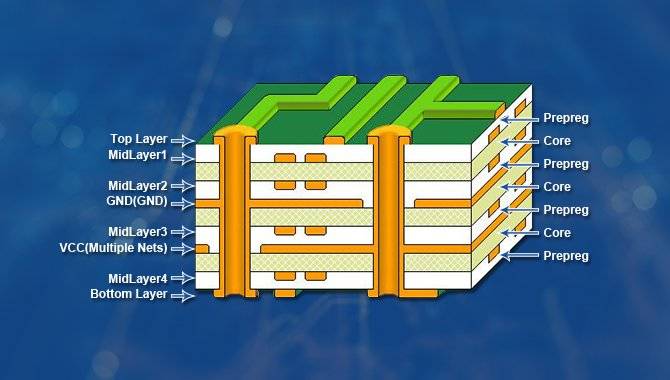

What is PCB Layer Stackup?

Our team focused on optimal multilayer stack-up because it is one of the most important factors in determining the EMC performance of a product.

For example, to improve the EMC performance of a 4 layer board, it is better to space the signal layers as close to the planes as possible and use a large core between the power and ground plane.

This is the most effective way to improve the performance of a 4 layer board. We can also balance well the Signal Integrity (SI) against manufacturability and reliability to have a good multilayer stack up.

PCB layer stackup is a way to getting multiple printed circuit boards in the same device by stacking them on top of each other while making sure there is a predefined mutual connection among them.

Important 4 tips before pcb layer stackup design

Tip #1: Determining the Number of Layers

This includes consideration of signal, power and grounding layers or planes. It is highly recommended that you do not mix signal types on the inner layers.

Tip #2: Determine the layer arrangement

Route high speed on microstrip of minimum thickness.

There should be a minimum spacing between the power and ground layers.

Tip #3: Determine layer material type

Another important consideration for PCB stackup is the thickness of each signal layer. This should be determined along with determining the thickness of the prepreg and core material.

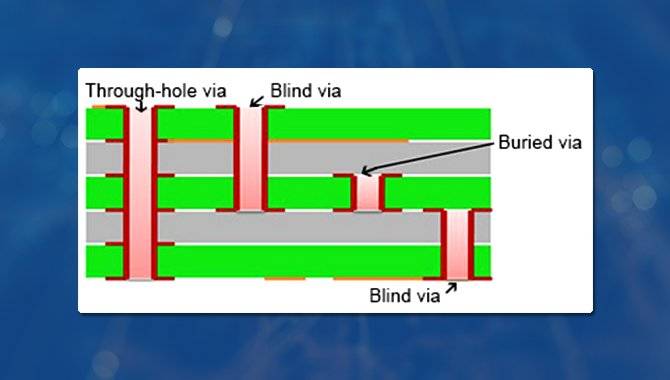

Tip #4: Determine routing and vias

Completing the PCB laminate design is the determination of the alignment and routing. This includes determining the weight of the copper, where to place the vias, and what type of vias to implement.

what is Power and ground layers in the layer stackup and its advantage

The power layer is the copper layer connected to the power supply. It is usually designated as VCC in PCB designs. The main function of the power layer is to provide a stable voltage supply to the PCB. Similarly, the grounding layer is a flat copper layer connected to a common ground point in the PCB.

Advantages of using a power/grounding layer

The component‘s power and ground pins can be easily connected to the power and ground planes.

It provides a clear path for current return, especially for high-speed signals. This, in turn, reduces EMI (electromagnetic interference).

The current carrying capacity of the power supply layer is larger than that of the alignment. The operating temperature of the PCB also can be reduced.

Blind and Buried Vias Layer stackup

Our team focused on optimal multilayer stack-up because it is one of the most important factors in determining the EMC performance of a product.

For example, to improve the EMC performance of a 4 layer board, it is better to space the signal layers as close to the planes as possible and use a large core between the power and ground plane.

This is the most effective way to improve the performance of a 4 layer board. We can also balance well the Signal Integrity (SI) against manufacturability and reliability to have a good multilayer stack up.

Certificeringer og overholdelse

DYC Electronic har etableret et omfattende teknologisk forsknings- og udviklingssystem.

✔ CCC-certificering

✔ ISO9001:2015 systemcertificering

✔ ISO14001:2015 systemcertificering

✔ ISO13485:2016 systemcertificering

✔ IATF16949-systemcertificering

✔ System til styring af forsyningskæden

✔ MES-system til sporing af processer

✔ Miljøstyringssystem