HASL vs ENIG: Choosing the Right PCB Surface Finish

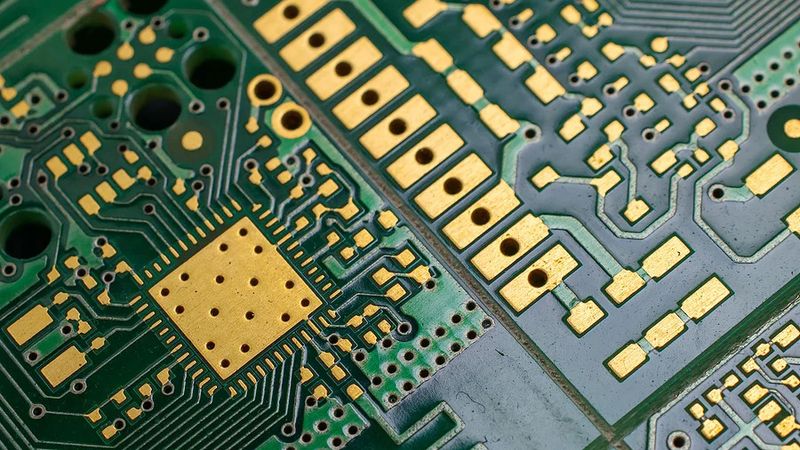

This article aims to provide a comparative analysis of HASL vs ENIG, providing valuable insights to aid in making informed decisions for PCB design and manufacturing HASL vs ENIG Surface Finish Introduction In PCB manufacturing, surface finishes play a crucial role in protecting exposed copper traces and ensuring optimal performance. These finishes act as a barrier against oxidation and facilitate reliable soldering connections, directly impacting the functionality and longevity of electronic devices. Two prevalent surface finishes, HASL (Hot Air Solder Level) and ENIG (Electroless Nickel Immersion Gold) have emerged as popular options due to their distinct advantages and disadvantages. The HASL process involves immersing the PCB in molten solder, followed by a hot air drying step. […]

Understanding the ENIG Finish: A Comprehensive Guide

This article delves into the basics of ENIG finish, its application process, advantages and disadvantages, challenges, and comparative analysis with other finishes. Printed Circuit Board with Electroless Nickel Immersion Gold Introduction In the world of electronics, The ENIG finish, or Electroless Nickel Immersion Gold, is a critical aspect, particularly in Printed Circuit Board (PCB) manufacturing. This type of finish is applied to the copper surface of a PCB to protect it from oxidation and to prepare it for subsequent soldering of components. The ENIG finish is important because it provides a reliable and robust surface for soldering, which is essential for the performance and longevity of electronic devices. It is […]

Types of Printed Circuit Boards: A Comprehensive Guide

This article delves into the various types of printed circuit boards, their fundamental concepts, structures, manufacturing processes, and advanced PCB technologies, highlighting their advantages, limitations, and typical applications. Types of Printed Circuit Boards Introduction Printed circuit boards (PCBs) are the foundation of modern electronics, providing a reliable method of connecting electronic components. These boards consist of conductive tracks, pads, and other features etched from copper sheets laminated onto a non-conductive substrate, such as FR-4. PCBs are crucial in various applications, from consumer electronics to industrial equipment and aerospace systems. The different types of printed circuit boards, including single-sided, double-sided, and multi-layer boards, cater to specific design requirements and constraints. Advanced […]

What are Circuit Boards Made Of? An Extensive Guide to Materials and Manufacturing Processes

Unveiling the Art and Science Behind Circuit Boards – Copper Etching to Silkscreens, a Comprehensive Guide to Elements, Manufacturing Processes, and Multilayered Varieties in Electronic Circuit Boards What are Circuit Boards? Circuit boards, also known as printed circuit boards (PCBs), are the backbone of virtually all modern electronic devices. From smartphones and computers to advanced medical equipment and electric vehicles, circuit boards play a crucial role in the functionality of these devices. They are perhaps the most critical part of modern electrical and electronic systems. A circuit board is a physical piece of technology that allows for the creation of complex electronic circuits. It’s the foundation upon which electronic components such as […]

Flexible PCBs in Modern Engineering

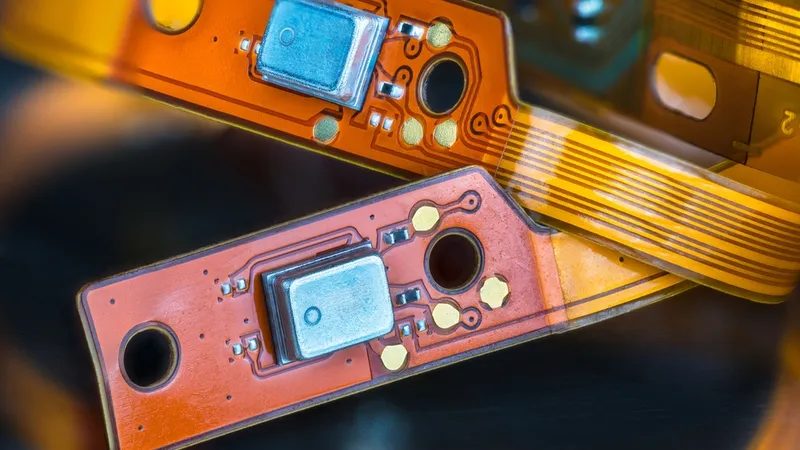

This article delves into the innovative world of flexible printed circuit boards, uncovering their design, advancements, and transformative role in modern engineering applications. PCB or small components on flexible ribbon cables Introduction Flexible printed circuit boards (PCBs) have revolutionized electronic circuit design with their ability to conform to various shapes and spaces, unlike traditional rigid-flex PCBs. Flexible PCBs are made from materials like polyimide or polyester film, allowing them to withstand repeated bending without losing their structural integrity. This flexibility makes them ideal for compact and robust electronic designs, as the copper traces etched onto these substrates maintain conductivity even when bent. Their distinct properties have made flexible PCBs a critical component […]

SMD Resistor Sizes: A Comprehensive Guide for Engineers

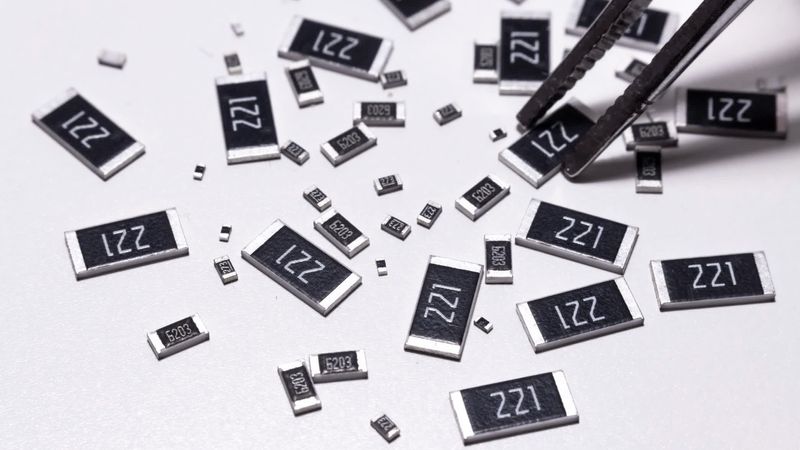

Learn about the various sizes of SMD resistors, their impact on electronic circuit design, and the latest technological advancements in SMD Resistor Technology. This guide discusses practical insights for engineering professionals looking to optimize their designs with precise resistor sizes. Introduction Surface-Mount Device (SMD) resistors are critical components in modern electronic circuits, offering compactness and reliability. These resistors are integral to the design of high-density circuits, enabling the miniaturization of electronic devices. SMD Resistor sizes play a crucial role in circuit design, influencing impedance, heat dissipation, and overall performance. Understanding the various SMD resistor sizes is essential for engineers aiming to optimize their designs for efficiency and functionality. Mastery of […]

Guide to PCB Mounting: Techniques, Tips, and Best Practices

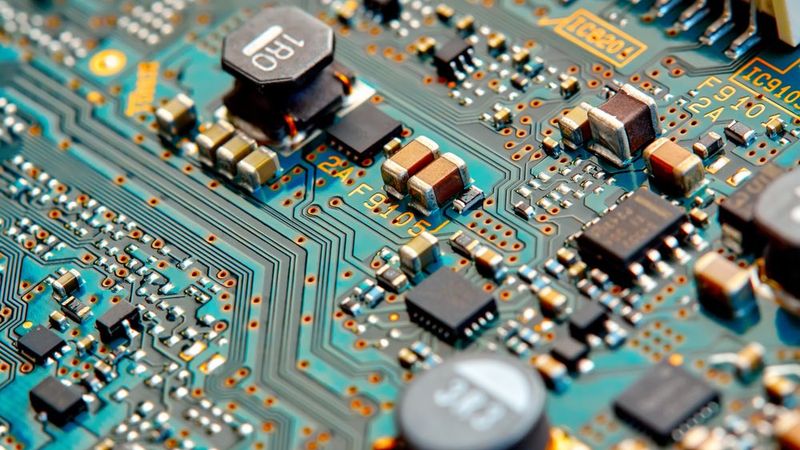

PCB mounting is critical for ensuring the lifetime and dependability of electronic products, including careful component selection and location, adherence to industry standards, and the use of high-quality materials and assembly procedures. This post will go over PCB mounting techniques, tips, and best practices and expand on crucial aspects of printed circuit board mounting. A Printed Circuit Board Introduction PCB mounting is an important aspect of electronics manufacturing and assembly, as it affects the performance and reliability of electronic devices. Understanding the best practices and techniques for PCB mounting has become increasingly important for industry professionals as electronic products become more complex. This comprehensive guide aims to provide an in-depth […]

Types of SMD Components: A Comprehensive Guide

This article delves into the various types of SMD components, detailing their sizes, functions, soldering techniques, selection guidelines, and applications. Printed Circuit Board with Surface Mounted Devices Introduction Surface Mount Device (SMD) components are integral elements in the world of electronics. These tiny devices have paved the way for miniaturized circuits, enabling sleeker designs and enhanced performance. SMD components play a crucial role in the functioning of electronic circuits, making it essential for anyone involved in electronics to understand them. Whether you’re an electronics enthusiast, a professional engineer, or simply curious about the inner workings of your everyday devices, this guide will provide you with a comprehensive understanding of SMD […]