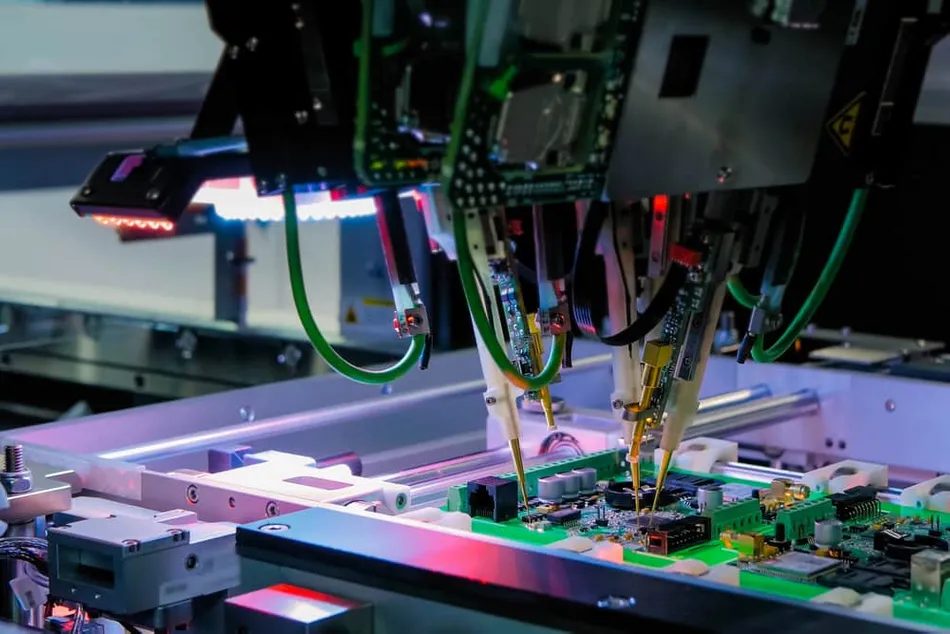

Mastering PCB Testing: Techniques, Methods, and Best Practices Unveiled

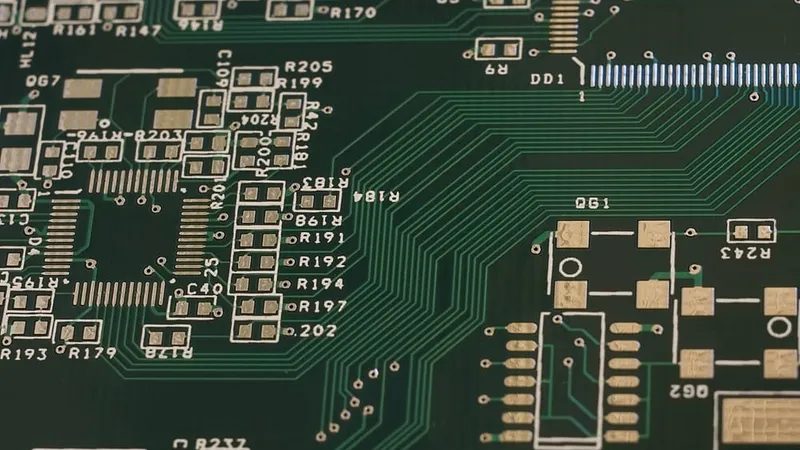

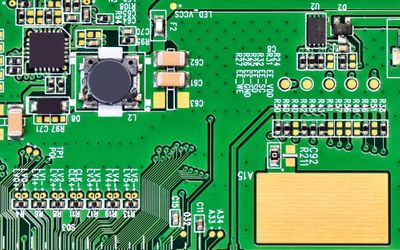

Testing PCBs involves using various methods and tools to ensure that all the individual elements of a PCB perform optimally, making up a high-quality PCB assembly. This article delves into the methods, procedures, and requirements of PCB testing. Electronic Circuit Board Introduction to PCB Testing Testing is integral to PCB manufacturing, ideally conducted throughout the production […]

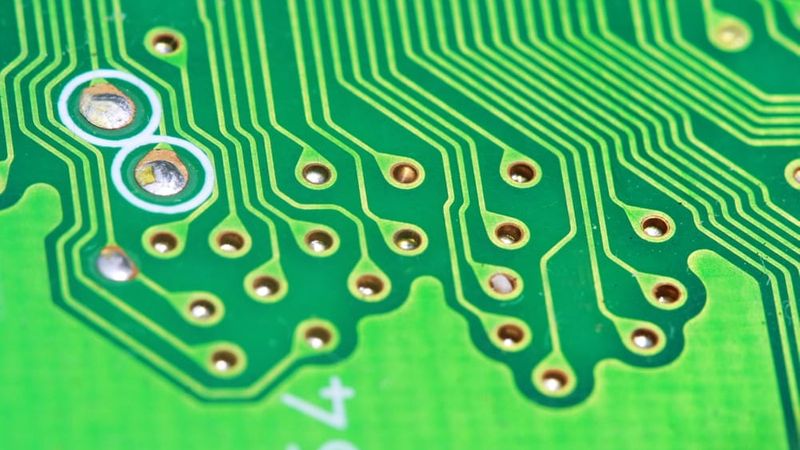

Via Tenting: A Comprehensive Guide to PCB Design and Manufacturing Techniques

Vias are small holes in a PCB that enable electrical connections between different layers of the board. In the context of PCB design, via tenting refers to the process of covering the vias with a protective layer, typically a solder mask or dry film. This protective layer shields the vias from environmental factors, such as […]

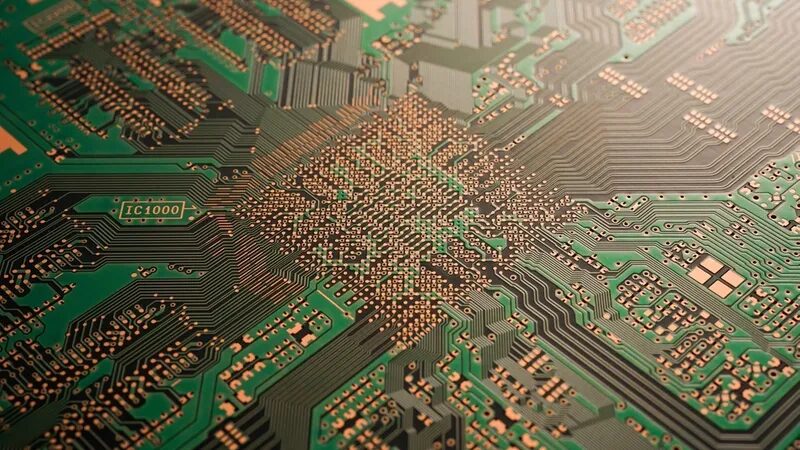

Micro vias : Pioneering the Future of PCB Design and Electronics Miniaturization

A microvia connects layers in HDI substrates and PCBs, enabling high input/output density in advanced packages. This article delves into the role and significance of microvias in modern electronics, exploring their impact on device miniaturization and functionality. PCB with a green solder mask and high-density interconnects Introduction Microvias represent a crucial innovation in printed […]

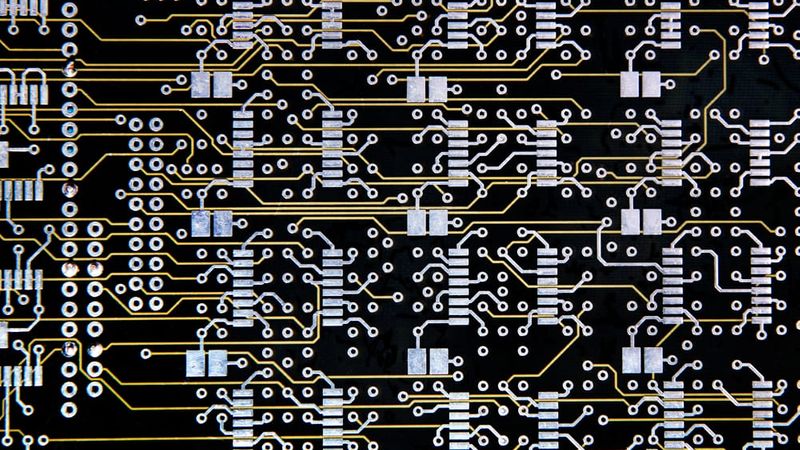

Bare Board Technology: Everything You Need to Know

Bare boards are the skeletal framework of printed circuit boards (PCBs). They are without electrical components which should have made it a fully functional PCB. This article details the uses, benefits, and drawbacks of bare boards, including the types of bare board testing. Bare printed circuit board Introduction The bare printed circuit board is […]

PCB Layers: Everything You Need to Know

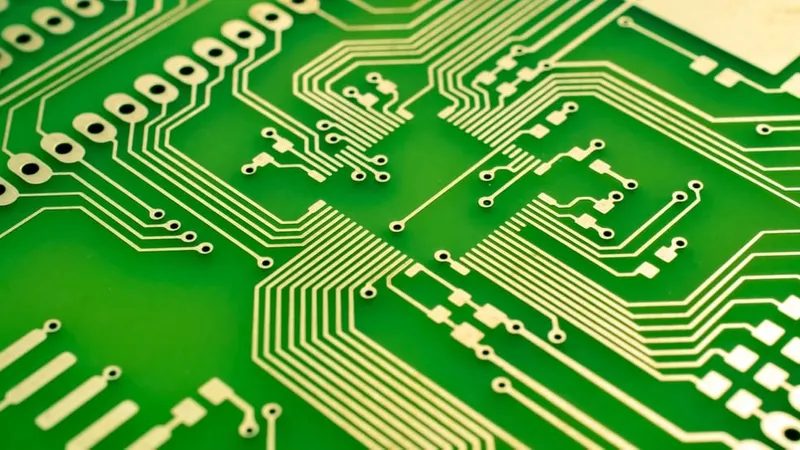

PCB layers are the copper layers within a printed circuit board, laminated between or onto layers of conductive material. These layers are stacked to enhance the functionality of electronic devices. This article explores the concept of PCB layering, the various types of layers, and their benefits. Multilayer Printed Circuit Board Introduction PCB layers are […]

PCB Via: Essential Guide to Vertical Interconnect Access in Circuit Boards

Printed Circuit Board Vertical Interconnect Access (PCB VIAs) are small plated holes that create electrical connections between different circuit board layers. This article delves into the various types, functions, and best practices of PCB VIAs to help you optimize your PCB design. Introduction A via, short for Vertical Interconnect Access, is an essential component […]

Quick Turn PCBs: Accelerating Innovation in Electronics Development

Quick turn PCBs are designed, fabricated, and assembled swiftly, ensuring tight schedules and deadlines are met, even for high-volume orders. This article investigates the quick turn PCB process, highlighting its benefits, stages, and how it guarantees quality within a short turnaround time. High-tech electronic PCB with processor and microchips Introduction In the fast-paced world of […]

PCB Trace: The Backbone of Modern Circuit Design

Introduction PCB trace technology is a cornerstone of modern electronic design, forming the intricate pathways that connect components on a printed circuit board (PCB). These conductive tracks ensure electrical signals are transmitted accurately and efficiently throughout the circuit. The design and quality of PCB traces can significantly influence the performance, reliability, and functionality of electronic […]